What can we do for you?

We work on all Cessna, Beechcraft & Piper single and twin-engine models

Annual Inspections/50Hr/100Hr Inspections

Inspection requirements differ with the various uses of aircraft. For example, aircraft being used for compensation or hire must have a thorough inspection every one-hundred hours. Most aircraft, including those used for compensation or hire are required to have a complete inspection every year.

Inspection requirements differ with the various uses of aircraft. For example, aircraft being used for compensation or hire must have a thorough inspection every one-hundred hours. Most aircraft, including those used for compensation or hire are required to have a complete inspection every year.

100-Hour Inspection (FAR 91.409)

The 100-hour inspection is required for aircraft:

The 100-hour inspection is required for aircraft:

That carry any person (other than a crew member) for hire; or

That are provided by any person giving flight instruction for hire.

The phrase "for hire" refers to the person, not the aircraft. An FAR Part 91 example of a person carried for hire is an aerial photography flight.

If a flight instructor provides an aircraft, or any operation that supplies both flight instruction and an aircraft, that aircraft is subject to the 100-hour inspection. An aircraft provided by the (student) pilot, who is receiving instruction, is not subject to the 100-hour inspection.

The 100-hour limit may be exceeded by 10 hours for the purposes of flying to a place where the inspection can be done. The excess time must be included in computing the next 100 hours of time in service.

Progressive Inspection (FAR 91.409)

Progressive inspections benefit owners whose aircraft experience high usage such as FBOs, flight schools, and corporate flight departments.

Progressive inspections benefit owners whose aircraft experience high usage such as FBOs, flight schools, and corporate flight departments.

Unlike an annual or 100-hour inspection, a progressive inspection allows for more frequent but shorter inspection phases, as long as all items required for the annual and 100-hour are inspected within the required time.

Example: Flight schools with aircraft that must comply with the 100-hour inspection normally use four inspection phases at 25-hour intervals. The inspection cycle is completed when the last inspection is endorsed.

The authority to use a progressive inspection plan is non-transferable. Once the aircraft is sold, an annual (or if applicable, a 100-hour) inspection must be endorsed within 12 calendar months (or 100 hours) of the last complete cycle.

Most airframe manufacturers will provide a boilerplate progressive maintenance plan.

Pre Buy Inspections

The Prepurchase inspection is a pilot defined inspection typically done on an aircraft before purchase. The inspection can be a thorough as an annual and as measly as a glance over the aircraft. The purpose is to locate any "unknown" problems with the aircraft before buying it, and to have a mechanics opinion on the overall quality of the plane.

Oil Changes

Did you ever wonder why we need to change the oil so often?

Did you ever wonder why we need to change the oil so often?

It's not because the oil breaks down in service and its lubricating qualities degrade. The fact is that conventional petroleum-based oils retain their lubricating properties for a very long time, and synthetic oils retain them nearly forever.

Consider, for example, that most automobile manufacturers now recommend a 7,500-mile oil-change interval for most cars and light trucks. That's the equivalent of 150 to 250 hours of engine operation.

The reason we change oil in our aircraft engines every 25 to 50 hours is not because it breaks down. It's because it gets contaminated after 25 to 50 hours in an aircraft engine. In fact, it gets downright filthy and nasty.

Dihydrogen monoxide (DHMO) is a highly corrosive chemical that is produced in copious quantities during combustion, and can cause great harm to costly engine components when it blows by the piston rings and contaminates the engine oil. You may be more familiar with DHMO's common chemical formula: H2O.

Compared with automotive engines, our piston aircraft engines permit a far greater quantity of combustion byproducts—notably carbon, sulfur, oxides of nitrogen, raw fuel, partially burned fuel, plus massive quantities of the corrosive solvent dihydrogen monoxide or DHMO to leak past the piston rings and contaminate the crankcase. This yucky stuff is collectively referred to as "blow-by" and it's quite corrosive and harmful when it builds up in the oil and comes in contact with expensive bottom-end engine parts like crankshafts and camshafts and lifters and gears.

Tire Changes

Some tire manufacturers publish minimum tread depths, which mandate tire replacement. As a general rule, if the tire tread has been worn to the base of any groove anywhere on the tire, it should be replaced. Exposure to the sun and aging can also damage a tire. This is called weather checking and usually shows up as numerous small cracks in the sidewall and bead areas, but it can also occur right in the tread. As with cuts, cracks extending down to the plys of the tire should mandate tire replacement.

Some tire manufacturers publish minimum tread depths, which mandate tire replacement. As a general rule, if the tire tread has been worn to the base of any groove anywhere on the tire, it should be replaced. Exposure to the sun and aging can also damage a tire. This is called weather checking and usually shows up as numerous small cracks in the sidewall and bead areas, but it can also occur right in the tread. As with cuts, cracks extending down to the plys of the tire should mandate tire replacement.

Another common tire problem is flat spots on the tread—often caused by skidding or hydroplaning during landing. Generally, tires do not need to be replaced due to flat spots unless the wear exposes the tire fabric.

Battery testing/replacement

Batteries take a beating, especially in cold temperatures. Every time you fly, your alternator and voltage regulator are working to keep your battery charged and healthy. However, as soon as you shut down, your battery slowly begins to lose its charge and degrade internally. All aircraft batteries, both flooded-cell "wet" batteries and sealed, absorbed glass mat batteries, require regular use in order to perform at their peak—that means putting them through cycles of discharging and recharging without reaching critically low voltage levels that can permanently damage the battery.

Critically low batteries begin a process of sulfating, where lead sulfate crystals form on the negative cells, reducing their effectiveness and eventually shorting them out. Neglecting an aircraft battery until it can no longer start the aircraft can inflict irreversible damage. Cold winter temperatures bring additional issues because batteries perform at their best when they are warm (but not hot). In fact, a very cold battery will not properly take a charge at all.

Propeller Installations

McCauley recommends that their fixed-pitch propellers be overhauled every seven years or 2,000 hours, while Sensenich only uses 2,000 operating hours as the TBO for their propellers. These overhauls are important, both for safety and performance. Stresses build up in the outer surfaces of the blades that can be relieved by resurfacing the blade and treating for corrosion. However, another important benefit of the overhaul is the inspection and correction of blade tracking and pitch.

McCauley recommends that their fixed-pitch propellers be overhauled every seven years or 2,000 hours, while Sensenich only uses 2,000 operating hours as the TBO for their propellers. These overhauls are important, both for safety and performance. Stresses build up in the outer surfaces of the blades that can be relieved by resurfacing the blade and treating for corrosion. However, another important benefit of the overhaul is the inspection and correction of blade tracking and pitch.

Owners of constant-speed propellers generally know the TBO of their propellers and also know that, if left unchecked, small problems can become very expensive ones. Dynamic propeller balancing should also be a part of your routine maintenance regimen. Think of it as an investment in the health of your aircraft, and in your personal flight experience.

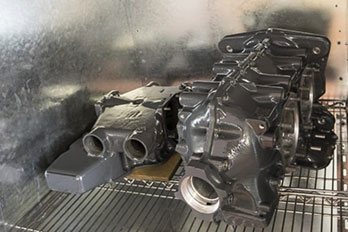

Engine Installations

A well-executed engine installation starts the minute the cowling is off, prior to the removal of the old engine. This is the best time to start planning for the comprehensive refurbishment of the engine accessories and airframe systems that make up a complete engine installation.

A well-executed engine installation starts the minute the cowling is off, prior to the removal of the old engine. This is the best time to start planning for the comprehensive refurbishment of the engine accessories and airframe systems that make up a complete engine installation.

A pre-removal inspection includes checking items such as the cowl flap and hinges, the engine mount (for rust, cracks, and corrosion), cowl supports and cowling attachment hardware, cooling baffles and cooling baffle seals, flexible hoses (for age as well as condition), exhaust system, turbocharger and wastegate, and induction filter and induction ducting sheetmetal.

The many pieces of specially shaped and cut aluminum that form the cylinder cooling baffles, and the flexible, rubberized material that nestles against the cowling to create the engine cooling system are vital for good engine health. Most engines come with intercylinder baffles that direct the cooling air to the cylinder cooling fins. These baffles are considered engine parts — all other baffle parts are airframe parts. Every piece, no matter how small, is vital. If the pieces are worn, cracked, or missing, buy new ones or repair any that are marginal yet worth salvaging.

Engines must be pre-oiled prior to the first start.

The first ground run is done with the cowling off. The first start consists of a low rpm operational check. Start the engine and run it at 1,200 rpm until the oil pressure starts to come off the peg — then increase the rpm to 1,800 to relieve camshaft lobe pressures. Limit the first run to three minutes.

Near the end of the three-minute time limit, pull the rpm back to idle and move the magneto switch very quickly to off, then right back on — the engine should sag, then come back on. Be quick on the off-position test. This test ensures that the magnetos are properly grounded. If a thorough visual inspection shows that there are no leaks and all systems operate normally, it's time to take the airplane for a flight.

Starter/Alternator replacement

Most alternators should be inspected every annual or 100 hours for general condition with a more significant, internal inspection every 500 hours. Certain alternators, such as the direct-drive models found on some Continental Motors engines, have additional inspection requirements.

Most alternators should be inspected every annual or 100 hours for general condition with a more significant, internal inspection every 500 hours. Certain alternators, such as the direct-drive models found on some Continental Motors engines, have additional inspection requirements.

Inspecting the alternator begins where the alternator gets its own power: the belt. Every 100 hours or annually, the belt should be checked for condition, proper tension, and alignment of the pulleys. The wear on the contact surface of the belt is an important indicator of the alignment and tension. Moving to the alternator itself, inspect the electrical connections, including the capacitor if equipped. All wires should be secure and free of abrasions.

The alternator itself should be fairly clean without significant carbon dust. If you note a lot of carbon, request an internal inspection even if the alternator is not yet due for it. It could mean excessive wear of the brushes, which will call for an internal inspection and maintenance that should be accomplished every 500 hours or anytime that you suspect a problem.

Electrical troubleshooting/repairs

Your aircraft's electrical system has three primary components: a battery, a generator or alternator, and an electrical bus to distribute electrical power. The spark plugs in certified piston aircraft engines are powered by engine-driven magnetos, so no additional electrical power is required for the engine to run.

A master switch, which usually has two halves—one controlling the battery, and another for the alternator or generator—enables the flow of power to aircraft systems. (It also allows the battery or alternator/generator to be turned off, helpful if electrical-system troubleshooting is required.) A voltage regulator maintains a constant system voltage, and an ammeter or loadmeter confirms the health of the system; it also indicates whether the battery is charging normally. Finally, a system of switches, fuses, and circuit breakers allow various components to be turned on and off, and protect them from excess current. In many aircraft electrical switches also incorporate circuit breakers.

LED wingtip/bulb replacements

To fly at night, an airplane must have approved anticollision and position lighting systems. (Airplanes certified prior to 1957 can legally get away with only position lights.) Position (or navigation) lights are steady-burning lights that allow you to quickly ascertain whether another airplane is coming, going, or crossing your path. The red and green wingtip position lights shine forward and out to the side while a white light covers your rear. Since steady-burning lights of only 40 watts or so don't draw much attention, anticollision lights are a must for anyone who does any measurable amount of night flight.

Light-emitting diodes (LEDs) are being certified for use as replacement position lights in general aviation airplanes. In addition, landing lights that use halogen and xenon technology continue to find their way into more light aircraft. The xenon and LED lights promise bulb life measured in thousands of hours, making bulb replacement an event to occur once every generation. In addition, LED and xenon lights deliver more candlepower while simultaneously drawing less current from the airplane's electrical system.

E-Mag installations

Electronic ignition has many advantages over traditional magnetos, including variable timing, a more powerful and longer lasting spark, fewer moving parts, and the ability to use low-cost automotive spark plugs. In practical terms, engines with electronic ignition are easier to start, consume less fuel, and have better high-altitude performance.

Electronic ignition has many advantages over traditional magnetos, including variable timing, a more powerful and longer lasting spark, fewer moving parts, and the ability to use low-cost automotive spark plugs. In practical terms, engines with electronic ignition are easier to start, consume less fuel, and have better high-altitude performance.

The biggest advantage magnetos have is that they create their own power, so they will continue to operate if the aircraft electrical system fails. E-Mag addresses this issue by installing a tiny alternator in each of its electronic ignitions that puts out enough power to keep E-Mags running on their own without external power. In case of an aircraft electrical failure, E-Mags are designed to keep the engine running just as magnetos would.

UAvionix Wing/Tail Beacon installation

By replacing your existing rear position light with UAvionix's tailBeacon, you're getting a 2x brighter LED nav light with a fraction of the power consumption. With tailBeacon's 20,000 hour rated LEDs, you can fly with confidence.

By replacing your existing rear position light with UAvionix's tailBeacon, you're getting a 2x brighter LED nav light with a fraction of the power consumption. With tailBeacon's 20,000 hour rated LEDs, you can fly with confidence.

The structure of a light metal aircraft is a collection of aluminum sheets, ribs, and stringers held together with hundreds of small metal fasteners called rivets.

The structure of a light metal aircraft is a collection of aluminum sheets, ribs, and stringers held together with hundreds of small metal fasteners called rivets.

The slightly rounded or, in some cases, flush heads of these rivets are found all over the outside skin of a typical light airplane. Rivets are used to join two sheets of aluminum, and to secure the skeletal ribs and stringers to the aluminum skins.

Airplanes are mostly hand made, and a big part of the job is bucking all of those rivets. It's usually a two-person job. The small, mushroom-shaped aluminum rivet is inserted into aligned holes that have been drilled through the parts to be joined. One person then applies the drive, which is basically a small air-powered jack-hammer-type tool, to the head of the rivet. The second person wields the bucking bar, which is little more than a heavy metal bar held against the backside, or buck-tail, of the rivet.

Riveting is a skill taught to and practiced by aviation mechanics because it is a fundamental process in sheet-metal repair.

Interior repair/replacement

Proper performance involves a careful and informed approach to a task that may seem trivial, but could have dire consequences if performed incorrectly. Take the example of removing or installing seats. Removing seats seems simple enough, but if you are removing the seats to carry cargo that means that you are responsible for properly securing the cargo. This could mean using built-in hard points and installing cargo nets. Installing seats is even more critical, as many accidents have been caused by improperly installed seats that were not properly secured to the seat tracks. If you are removing doors or windows, there may be other considerations regarding the safety and security of the occupants and any loose items on board.

Every step in the maintenance manual must be carefully followed to ensure that the aircraft is safe and airworthy following the modification.

Proper performance also means understanding and accounting for the weight and balance change to the empty weight of the aircraft. This leads us to proper documentation. Seats, doors, windows, floats, or skis are not the same as passengers and carry-on baggage and should not be accounted for in the same way. It is not legal, or appropriate, to simply pull out a couple of seats, run a typical preflight weight and balance calculation, and take off.

Major repairs & Alterations per FAA guidelines.

The regulations classify aircraft repairs as being either major or minor. A major repair is one "(1) That, if improperly done, might appreciably affect weight, balance [limits], structural strength, performance, powerplant operation, flight characteristics, or other qualities affecting airworthiness; or (2) That is not done according to accepted practices or cannot be done by elementary operations." Repairs other than major repairs are minor.

A major repair is one that the FAA wants to know about. It must be done in accordance with "approved data" that has been officially blessed by an authorized representative of the administrator (typically an FAA engineer, inspector, or designated engineering representative). It must be inspected and approved by a technician with inspection authorization (IA), documented on an FAA Form 337 (record of major repair or alteration), and filed with the FAA Records Branch in Oklahoma City, where it becomes a permanent part of the aircraft's official records.